Compressors Guide

Type of compressor: reciprocating, rotary screw, centrifugal

There are three main types of compressors to choose from: reciprocating, rotary screw, and centrifugal.

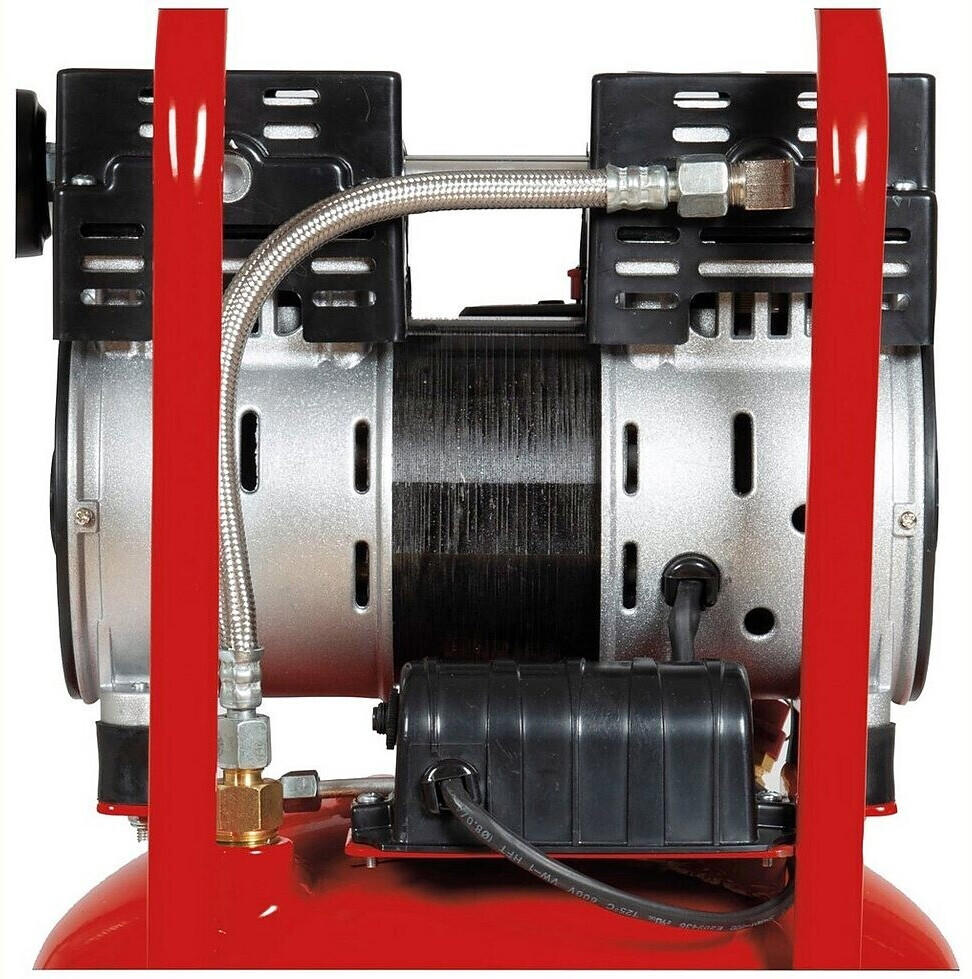

A reciprocating compressor, such as the Ingersoll Rand Type 30 model, uses positive displacement to compress air. It is ideal for applications that require high pressure, such as powering pneumatic tools or operating heavy machinery. This type of compressor is known for its durability and efficiency.

On the other hand, a rotary screw compressor like the Atlas Copco GA Series offers a continuous supply of compressed air. It works by using two interlocking helical rotors to compress the air. This type of compressor is well-suited for industries that require a constant and sustained air flow, such as manufacturing and automotive.

Lastly, a centrifugal compressor, like the GE Oil & Gas Howden model, uses centrifugal force to compress air. It is commonly used in large-scale industrial applications due to its ability to handle high volumes of air. This type of compressor offers high efficiency and low maintenance, making it a popular choice for processes like gas production and oil refining.

In summary, the different types of compressors have distinct features and suitability for specific applications. Reciprocating compressors are best for high-pressure applications, while rotary screw compressors offer a continuous supply of compressed air. Centrifugal compressors are suitable for large-scale industrial processes. It is important to consider these factors when choosing the best compressor for your needs.

Power source: electric, gasoline, diesel, pneumatic

The choice of power source will depend on your specific needs and requirements.

Electric compressors: These compressors are ideal for indoor use or in areas where electricity is readily available. They offer quiet operation, zero emissions, and low maintenance. One example of an electric compressor is the

DEWALT DWFP55126 Pancake Compressor, which operates at 120V of electricity and delivers a maximum pressure of 165 PSI.Gasoline compressors: These compressors are excellent for outdoor use, construction sites, and areas without access to electricity. They offer portability and provide higher pressure outputs. A notable example is the

California Air Tools CAT-10020C Ultra Quiet Portable Air Compressor, powered by a 2 HP gasoline motor and offering a pressure of up to 125 PSI.Diesel compressors: These compressors are suitable for heavy-duty applications and remote locations where electricity or gasoline may not be readily available. They provide high performance and durability. One example is the

DEWALT DCC1150B 15-Gallon Diesel Wheeled Portable Air Compressor, which features a durable diesel engine and offers a maximum pressure of 121 PSI.Pneumatic compressors: Also known as air compressors, these models use compressed air as their power source. They can be driven by rotating machinery such as an engine or motor. Examples include the

Ingersoll Rand P1.5IU-A9 2-HP 30-Gallon Pneumatic Air Compressor, which operates on 115V of electricity and offers a maximum pressure of 135 PSI.

Capacity: measured in cubic feet per minute (CFM)

Measured in cubic feet per minute (CFM), a higher CFM signifies a greater air output. Whether you're using a compressor for small DIY projects or industrial applications, finding the right CFM rating is crucial.

For small DIY projects and household use, a compressor with a lower CFM such as the PORTER-CABLE C2002-WK Oil-Free UMC Pancake Compressor is a great choice. With a CFM rating of 2.6 at 90 PSI, it provides sufficient power for tasks like inflating tires or running pneumatic nail guns.

For medium-sized projects or professional use, a compressor with a mid-range CFM like the DEWALT DXCMV5048055 Two-Stage Two-Cylinder High CFM Compressor is recommended. This heavy-duty compressor offers a CFM rating of 17.9 at 175 PSI, making it suitable for running multiple tools simultaneously and powering larger equipment.

Lastly, for demanding industrial applications where a high CFM is essential, the Ingersoll Rand 2545K10-V Two-Stage Electric-Driven Air Compressor is an excellent choice. With a CFM rating of 35 at 100 PSI, this compressor is designed to handle heavy-duty tasks in manufacturing plants, workshops, and construction sites.

Remember, when selecting a compressor, the CFM rating is crucial to ensure that it meets the air requirements of your specific project.

Maximum pressure: measured in pounds per square inch (PSI)

The maximum pressure determines the amount of force the compressor can produce, and it is crucial for applications that demand high-pressure outputs. For example, the Kobalt 30-Gallon Two Stage Portable Electric Vertical Air Compressor provides a maximum pressure of 175 PSI, making it suitable for heavy-duty tasks such as operating air tools in automotive and construction settings. In contrast, the PORTER-CABLE C2002-WK Pancake Air Compressor offers a maximum pressure of 150 PSI, making it ideal for lighter applications such as inflating tires or running small air-powered tools. By considering the maximum pressure of compressors, you can ensure they can meet the requirements of your specific tasks.

Size and portability: compact, portable, stationary

The first step is to decide whether you need a compact, portable, or stationary compressor based on your specific requirements and intended usage.

If you're looking for a compact and portable compressor that can be easily transported to different job sites, the Dewalt DWFP55126 Pancake Compressor is an excellent option. With a size of just 17.2 x 16.6 x 20.1 inches and a weight of 30 lbs, it offers ease of mobility without compromising on performance. Another great choice is the California Air Tools CAT-6310 Ultra Quiet and Oil-Free Air Compressor, which is 23.6 x 14 x 18 inches in size and weighs only 58 lbs. Its compact design and wheels make it easy to move around.

If you require a stationary compressor for a workshop or a fixed location, the Industrial Air ILA3606056 Vertical Stationary Air Compressor is a solid choice. It has a larger footprint with its 33.5 x 22 x 69 inches dimensions and weighs approximately 471 lbs, making it intended for permanent installation. Another high-quality option is the Ingersoll Rand SS3L3 Single-Stage Air Compressor, which is specifically designed for continuous-duty applications and features a 60-gallon horizontal tank for maximum air capacity.

Remember to consider both the size and portability when selecting the compressor that best suits your needs.

Noise level: decibels (dB)

Noise can be a concern if the compressor will be used in a residential or noise-sensitive area. Some compressors are designed to operate quietly, making them the ideal choice for those who prioritize a quiet working environment.

One example of a compressor with a low noise level is the California Air Tools CAT-1P1060SP Quiet Air Compressor. With a noise level of only 56 decibels, this compressor ensures a peaceful work setting. Another option is the Makita MAC2400 Big Bore Air Compressor, which operates at just 79 decibels, providing a quieter experience compared to many other compressors on the market. These are just a couple of examples of compressors that prioritize minimizing noise levels, making them suitable for residential or noise-sensitive areas.

Duty cycle: the percentage of time the compressor can run continuously

A higher duty cycle allows for longer operation, making it ideal for industrial or heavy-duty applications. One example of a compressor with a high duty cycle is the Ingersoll Rand SS3F2-GM Garage Mate 15 Amp 2 Horsepower 30 Gallon Oiled Wheeled Single Hot Dog Compressor. With a duty cycle of 100%, this compressor can provide continuous operation without any downtime, making it perfect for professional workshops and intensive use.

On the other hand, if you require intermittent use or lighter tasks, a compressor with a lower duty cycle may suffice. For instance, the California Air Tools 8010 Steel Tank Air Compressor has a duty cycle of 50%, meaning it can run for half of each hour. This compressor is portable and suitable for small-scale applications such as inflating tires or operating airbrushes.

It's noteworthy to mention that compressors are often categorized into two groups based on their intended duty cycle - continuous and intermittent duty compressors. Continuous duty compressors can operate for extended periods without overheating, while intermittent duty compressors are better suited for shorter bursts of usage.

Tank capacity: measured in gallons

The tank capacity determines how much air the compressor can store and deliver to your tools or equipment. A larger tank capacity allows for longer periods of continuous operation without the need to wait for the tank to refill. For example, the DeWalt DXCM271.com features a 27-gallon tank capacity, giving you ample air supply for your projects. Similarly, the Industrial Air ILA1883054 boasts a 30-gallon tank capacity, ideal for heavy-duty applications. For those needing a larger tank capacity, the Industrial Air IL3106016 offers a massive 60-gallon tank, ensuring extended operations without interruptions.

Number of stages: single-stage, two-stage

Compressors typically come in two stages: single-stage and two-stage. Single-stage compressors have one piston that compresses the air to the desired pressure in a single stroke. They are simple to operate and suitable for light-duty tasks such as inflating tires or powering small pneumatic tools. An example of a single-stage compressor is the California Air Tools 2010A which is capable of delivering air at a pressure of up to 120 PSI.

On the other hand, two-stage compressors have two pistons, one low-pressure and one high-pressure, that work in tandem to achieve higher air pressure. They provide more power and can handle heavy-duty tasks such as operating air tools or powering large industrial equipment. An excellent example of a two-stage compressor is the Ingersoll Rand SS5L5 which can deliver air at pressures up to 175 PSI and has a large air tank capacity of 60 gallons. Two-stage compressors are more efficient and provide higher airflow, making them suitable for demanding applications.

Air filtration system: for clean air supply

Look for compressors that have efficient filtration systems designed to remove contaminants such as dust, particles, and moisture from the compressed air. A high-quality air filtration system also extends the life of your compressor and downstream equipment.

For example, the ingersoll-rand 2545K10-V is a popular option that features an advanced filtration system. It has a two-stage filtration process with a pre-filter to remove larger particles and a coalescing filter to remove oil and moisture. This compressor has a maximum pressure of 175 PSI and delivers 35 CFM at 100 PSI. It is suitable for industrial applications where clean and reliable compressed air is crucial.

Another option is the Campbell Hausfeld DC080500 compressor, which also offers an efficient air filtration system. This compressor has a three-stage filtration process that includes a wire screen, a fine fiber filter, and a desiccant dryer. It removes particulates and moisture down to 0.01 microns and provides clean and dry compressed air. The Campbell Hausfeld compressor has a maximum pressure of 125 PSI and delivers 9.6 CFM at 90 PSI. This makes it suitable for smaller applications where clean air is essential, such as painting or pneumatic tool use.

By focusing on the air filtration system and choosing compressors like the mentioned models, you can ensure a clean and reliable air supply for your specific needs.

Oil or oil-free lubrication system: maintenance requirements and air quality

Compressors with oil lubrication generally require regular maintenance such as oil changes and filter replacements. The oil lubrication system also introduces oil content into the compressed air, which can affect the air quality. If air quality is a crucial requirement for your application, especially in industries like electronics, pharmaceuticals, or food and beverage, an oil-free lubrication system is recommended.

An example of a compressor with an oil lubrication system is the Ingersoll Rand SS3F2-GM 2 HP 30 Gallon Single Stage Portable Air Compressor. This compressor uses oil lubrication and requires regular maintenance according to the manufacturer's specifications. If you prefer an oil-free option for improved air quality, the California Air Tools 8010 Steel Tank Air Compressor is a good choice. This compressor employs an oil-free lubrication system and delivers clean air suitable for sensitive applications.

Integration with other equipment: compatibility with tools or systems requiring compressed air

You want to ensure that the compressor you choose is compatible with the tools or systems requiring compressed air. One example of a compressor that offers seamless integration is the DeWalt DWFP55126 6-Gallon Pancake Compressor. It has a high flow regulator and couplers to maximize air tool performance. Additionally, the California Air Tools CAT-1P1060S Light & Quiet Portable Air Compressor is another excellent choice for integration. This compressor features a lightweight and quiet design, making it ideal for use with tools and equipment in both areas where noise is a concern and frequent transportation is required.

Other products on the market are segmented based on their capacity and purpose. For smaller applications such as home use or light-duty tasks, the Makita MAC700 Big Bore Air Compressor is a reliable option with its continuous duty rating and low AMP draw. On the other hand, for larger industrial applications, the Ingersoll Rand 2475F13GH Duplex Compressor provides exceptional integration capabilities with its duplex design and 100% continuous duty cycle.

Control panel: ease of use and options for pressure adjustment

The control panel should be user-friendly and provide convenient options for pressure adjustment. One example of a compressor with an easy-to-use control panel is the 'California Air Tools 8010'. This compressor features a simple control panel with an easy-to-read pressure gauge and adjustable pressure settings. The control panel allows users to easily adjust the desired pressure level based on specific requirements.

Another option to consider is the 'Makita MAC2400'. This compressor offers a user-friendly control panel with pressure adjustment options. The pressure regulator knob allows precise pressure settings, optimizing the air tools' performance. Additionally, the gauges on the control panel provide accurate readings for efficient operation.

Other compressors on the market can be divided into different segments based on their control panel features. In the budget-friendly segment, the 'PORTER-CABLE C2002-WK' is a popular choice. This compressor's control panel offers ease of use with its quick-connect coupler and conveniently placed regulator knob for pressure adjustments.

On the higher end of the market, the 'Rolair JC10 Plus' is known for its sophisticated control panel. It features a digital display that shows the current and target pressure levels, providing precise control during operation.

In conclusion, when choosing a compressor, it is important to consider the control panel's ease of use and options for pressure adjustment. Examples such as the 'California Air Tools 8010', 'Makita MAC2400', 'PORTER-CABLE C2002-WK', and 'Rolair JC10 Plus' are all great options that provide user-friendly control panels with convenient pressure adjustment features.

Motor horsepower (HP): the power of the compressor

Motor HP refers to the power output of the compressor and determines its ability to deliver compressed air effectively. A higher motor horsepower generally indicates a more powerful compressor that can handle larger workloads and provide increased air pressure.

For small-scale applications and projects like inflating tires or powering light-duty air tools, a compressor with a motor horsepower range of 0.5 to 1 HP will suffice. Popular options in this category include the PORTER-CABLE C2002-WK Oil-Free UMC Pancake Compressor with a 0.8 HP motor or the DEWALT DWFP55126 Pancake Compressor with a 0.9 HP motor.

For medium-sized tasks and jobs that require a bit more power, a compressor with a motor horsepower range of 1.5 to 4 HP is recommended. This category offers a wider selection of compressors, such as the Makita MAC5200 Big Bore Air Compressor with a 3.0 HP motor or the California Air Tools CAT-10020 Ultra Quiet Compressor with a 2.0 HP motor.

In the case of heavy-duty applications, a compressor with a motor horsepower of 5 HP or more is necessary to ensure sufficient air power. Such compressors are suitable for professional contractors and industrial-grade tasks. Examples include the Ingersoll Rand 2340L5-V Compressor with a 5.0 HP motor or the Industrial Air ILA1883054 Belt Driven Portable Compressor with an impressive 13.0 HP motor.

Remember to consider other factors, such as tank capacity and CFM (cubic feet per minute) while choosing the best and right compressor, but motor horsepower remains a crucial aspect in determining the compressor's power output.

Start-up method: electric start, pull start

There are primarily two types of start-up methods: electric start and pull start. Electric start compressors, such as the DeWalt DXCMLA1983012, provide convenience and ease of use. These compressors feature an electric ignition system, eliminating the need for manual pull-starting.

On the other hand, pull start compressors, like the CRAFTSMAN CMEC6150K, require manual effort to get started. With a simple pull of the recoil starter, these compressors kick to life. Pull start compressors are typically more affordable and straightforward in design.

Note that certain specifications might be mentioned in the product descriptions, such as horsepower (HP), tank capacity, pressure (PSI), airflow (CFM), noise levels, and pump type. It's crucial to understand these terms to make an informed decision.

Pricing and value for money

You want to ensure that you are getting the best bang for your buck without compromising on quality. One compressor that offers great value for money is the California Air Tools 5510SE compressor. Priced at around $140, it boasts a powerful motor that operates at a low noise level of only 60 decibels. With a tank capacity of 5.5 gallons and a maximum pressure of 120 PSI, it is suitable for a range of applications such as household maintenance or powering pneumatic tools. Another excellent option is the DEWALT DWFP55126 compressor, which is priced around $170. It features a 6-gallon tank and a maximum pressure of 165 PSI, making it ideal for heavy-duty projects. Overall, comparing pricing and specifications, these compressors offer great value for money in their respective segments.

Oil level indicator: visibility of oil levels for lubricated compressors

This feature is crucial for ensuring the proper lubrication and functionality of the compressor. An oil level indicator allows users to easily monitor and maintain the optimum oil levels, preventing potential damage to the compressor.

Several compressors on the market offer excellent oil level visibility. One such product is the Ingersoll Rand 2475N7.5-P, which features a large, easy-to-read sight glass. This sight glass provides a clear view of the oil levels, enabling users to quickly assess and adjust as necessary. Another option is the California Air Tools 10020C, equipped with a conveniently located oil level sight glass that simplifies the monitoring process. Both these compressors provide excellent visibility of oil levels, ensuring reliable operation and longevity of the compressor.

Safety features: overheating protection, automatic shut-off

Look for compressors that have built-in overheating protection, as this feature prevents the motor from overheating and causing potential damage. One example of a product that offers this safety feature is the PORTER-CABLE C2002 Oil-Free UMC Pancake Compressor. This compressor comes with a thermal overload protection feature which automatically shuts off the compressor when it reaches a certain temperature, preventing any accidents or damage.

Additionally, an automatic shut-off is a vital safety feature that helps prevent any accidents or overloads. The Makita MAC5200 Big Bore 3.0 HP Air Compressor is an excellent choice that includes an automatic shut-off feature. This compressor automatically turns off when the desired pressure is reached, keeping the machine safe and preventing the risk of over-pressurization.

It's worth noting that these safety features tend to be standard across most compressor brands and models since they are essential for user safety. However, always double-check the manufacturer's specifications and product details to validate the presence of overheating protection and automatic shut-off for the specific product you are considering.

Environmental impact: energy efficiency, emissions

Environmental Impact: Energy Efficiency and Emissions

When choosing a compressor, it is essential to consider its environmental impact, focusing on energy efficiency and emissions. Look for compressors that are designed to minimize energy consumption without compromising performance. Evaluating the compressor's efficiency can be determined by the specific power consumption, which is measured in kilowatts per cubic meter of compressed gas flow rate (kW/m³/min). Opt for compressors that have a lower specific power consumption as it indicates higher energy efficiency. Additionally, consider a compressor with advanced energy-saving features, such as load/no-load operation and variable speed drive (VSD) technology.

The emissions produced by a compressor should also be examined to ensure minimal impact on the environment. Look for models that comply with the latest emission standards, such as ISO 8573-1, which classifies air according to the presence of solid particles, water, and oil contaminants. One brand that exemplifies both energy efficiency and low emissions is the 'Atlas Copco ZR Series'. These oil-free rotary screw compressors boast impressive energy savings with specific power consumption ranging from 0.245 to 0.322 kW/m³/min. Furthermore, the 'Ingersoll Rand Next Generation R-Series' offers advanced variable speed drive compressors, delivering both efficient performance and reduced emissions thanks to its innovative air-scavenging cooling system and advanced rotor profile.

Adaptability for different applications: construction, automotive, industrial, etc.

Whether you need a compressor for construction, automotive, or industrial use, it's essential to find one that suits your specific requirements.

For construction purposes, a portable and durable compressor such as the PORTER-CABLE C2002-WK Oil-Free Pancake Compressor would be an excellent choice. With a compact design and 150 PSI of maximum pressure, this compressor can reliably power various construction tools such as nail guns, staplers, and drills.

In the automotive industry, an air compressor that can efficiently inflate tires and run air tools is indispensable. The Viair 450P-Automatic Portable Compressor Kit offers a maximum working pressure of 150 PSI and comes with an automatic shut-off function. Its compact size and heavy-duty construction make it suitable for tackling various automotive applications.

For industrial settings, a high-capacity compressor like the Ingersoll Rand 2475N7.5-V would be ideal. This reciprocating air compressor provides 175 PSI of operating pressure, making it suitable for handling demanding industrial tasks. With its deep-fin cylinder design and heavy-duty construction, this compressor can withstand long hours of continuous operation.

It's worth noting that the compressor market can be segmented based on capacity, power source, and specific applications. For lighter industrial applications, compressors such as the DEWALT DXCM271 Wall Mountable Compressor or the California Air Tools 10020C Ultra Quiet are suitable options. These compressors are designed for quieter operation and offer smaller tank capacities for more portable usage. In contrast, heavy-duty industrial applications may require more robust compressors like the aforementioned Ingersoll Rand model or the Industrial Air ILA4708065 80-Gallon Two Stage compressor, capable of supplying higher volumes of consistently high-pressure air.

When selecting a compressor, considering its adaptability for different applications is crucial. Remember to balance the specific power requirements, pressure capacity, and portable or stationary characteristics to find the best fit for your particular needs.

Operating temperature range: suitable for various climates

Different compressors have specific temperature limits within which they can efficiently operate. It is crucial to select a compressor that can withstand the wide range of temperatures in various climates.

One such compressor is the Makita MAC700 Big Bore Air Compressor, which is designed for a temperature range between 40°F to 90°F (4°C to 32°C). This compact and powerful compressor features a roll-cage construction and a low-amp draw to provide consistent performance in different climates.

Another option is the California Air Tools 8010 Ultra Quiet Air Compressor, which can operate in temperatures as low as 25°F (-4°C) and as high as 115°F (46°C). This oil-free compressor is known for its quiet operation and is suitable for users who need a compressor that can perform in a wide variety of climates.

In summary, when choosing a compressor, look for products like the Makita MAC700 and California Air Tools 8010 that offer an operating temperature range suitable for various climates.

Vibration and stability: rubberized feet or other mechanisms to reduce vibrations

To reduce vibrations and ensure stability, look for compressors that come with rubberized feet or other mechanisms designed to dampen vibration. For example, the Makita MAC5200 compressor features a built-in, rubberized feet that effectively minimizes vibrations and allows for a more stable operation. The Rolair JC10 compressor also includes rubberized isolators that significantly reduce vibrations and provide a solid and stable base. These features help prevent the compressor from moving around during operation, ensuring a smoother and more comfortable user experience.

Ease of maintenance: accessibility to components and filters

Easy access to these parts makes it simpler to perform routine maintenance and replace filters, ensuring the longevity and optimal performance of the compressor. For those looking for compressors with excellent ease of maintenance, the Campbell Hausfeld DC080500 is a great option. This compressor has a conveniently located panel that allows easy access to all internal components, saving time during maintenance. Another great choice is the Porter-Cable C2002-WK. With its easy-to-access oil-free pump and secured components, the compressor allows for hassle-free maintenance and filter replacement.

In terms of different compressor segments, two other noteworthy options include the Makita MAC2400 and the DeWalt D55146. Both fall under the portable air compressor segment and feature easily accessible parts and filters. The Makita MAC2400 boasts a large intake filter and its roll cage construction allows for convenient component access. On the other hand, the DeWalt D55146 features a low-profile design with a protective canopy, ensuring easy access and maintenance of its integral parts. These compressors provide efficient and user-friendly solutions for individuals seeking compressors with superior ease of maintenance.

Port connections: compatible with different hose types and sizes

It is essential that the compressor you choose has port connections that are compatible with different types and sizes of hoses. This will allow you to easily connect the compressor to the specific hose you need for your project.

An example of a compressor with versatile port connections is the BOSTITCH BTFP02012. This compressor features a high flow regulator and couplers that are designed to maximize air tool performance. It has a ¼" universal quick coupler that is compatible with various hose sizes, providing flexibility for different applications. The DEWALT DWFP55126 is another option worth considering. It is equipped with a ¼" NPT air outlet, which can accommodate both small and large diameter hoses, ensuring compatibility with a wide range of fittings.

Durable construction: materials used for longevity and reliability

Look for compressors that are built with high-quality components such as stainless steel valves, cast-iron cylinders, and robust motor systems. These elements contribute to the durability and overall lifespan of the compressor.

In the market, there are several notable manufacturers known for producing compressors with durable construction. One segment includes industrial-grade compressors designed for heavy-duty applications. Take, for example, the Ingersoll Rand 2340L5-V Sal Series which features a cast-iron construction, including the cylinders, crankcase, and flywheel. The pump is designed for maximum efficiency and longevity.

Another segment consists of portable compressors, ideal for DIY enthusiasts or contractors who require a reliable yet compact solution. The California Air Tools 8010 Ultra Quiet compressor utilizes a steel tank and impact-resistant shroud to ensure durability in various working environments.

Weight: ease of transportation and maneuverability

For those who need a compact and lightweight option, the 'Makita MAC700' compressor is an excellent choice. Weighing only 52 pounds, this compressor is designed with ease of portability in mind. Another lightweight option is the 'Bostitch BTFP02012' compressor, weighing just 29 pounds, making it extremely easy to move around.

For those who require a more powerful compressor in a portable package, the 'DeWalt DWFP55130' is a great option. Weighing 71 pounds, this compressor features a compact and vertical design, making it easy to transport and maneuver in tight spaces. In terms of even larger units, the 'California Air Tools 10TL' is worth considering. Weighing 103 pounds, it has a heavy-duty handle and wheels to ensure ease of transportation without compromising on power. These are just a few examples of compressors that prioritize weight for user convenience.

Pressure regulator: ability to adjust output pressure

The pressure regulator allows you to control the amount of pressure exerted by the compressor, ensuring it is suitable for your specific needs.

One excellent compressor that offers a reliable pressure regulator is the California Air Tools CAT-1P1060SP Quiet Air Compressor. This compact and lightweight compressor features a pressure regulator knob that allows you to easily adjust the output pressure to match your desired requirement.

Another option to consider is the Makita MAC2400 Big Bore 2.5 HP Air Compressor. This powerful machine also comes equipped with a pressure regulator that enables you to finely tune the output pressure according to your application.

Both of these compressors provide detailed specifications about their pressure regulators and the control mechanisms used. Understanding these specifications will allow you to choose the best compressor for your needs.

Extra features: built-in air dryer, pressure gauges, drain valves, etc.

One important feature to look for is a built-in air dryer. This extra feature removes moisture from the compressed air, preventing rust and corrosion in your tools and equipment. A great example of a compressor with this feature is the California Air Tools 8010DSPC, which comes equipped with a built-in air dryer system. Another extra feature to consider is pressure gauges, which allow you to monitor the air pressure inside the tank. This is beneficial for maintaining the optimal pressure for your specific application. The Bostitch BTFP02012 is a reliable choice that boasts a high-efficiency motor and an easy-to-read pressure gauge. Furthermore, drain valves are essential for regularly draining condensation from the tank, and the Industrial Air ILA1883054 is a durable and efficient compressor that offers easy access to its reliable drain valve.

Cooling system: efficiency in dissipating heat

One such example is the Ingersoll Rand 2475F13GH reciprocating air compressor, which features a highly efficient two-stage cooling system. The first stage utilizes an integral 55°C after-cooler to cool down the compressed air and reduce the amount of heat transferred to the intercooler. The second stage consists of a large two-pass cooling system that further cools the air before dissipation, providing superior heat rejection and enhancing the overall performance of the compressor.

In addition to the reciprocating models, rotary screw compressors also excel in their cooling capabilities. The Atlas Copco GA30+ - 50FF rotary screw air compressor is a prime example, equipped with an optimized cooling airflow design that facilitates effective heat transfer. It features a high-efficiency stainless steel cooler with an optional integrated water separator, allowing for efficient cooling and removal of condensates. Furthermore, the GA30+ - 50FF also incorporates a heat recovery system, which leverages the excess heat produced during compression for secondary applications such as heating air or water, enhancing overall efficiency. It's worth considering such compressors for their advanced cooling systems, ensuring the dissipation of heat for optimal performance.

Power cord length: convenience in reaching power source

A longer power cord provides convenience in reaching the power source, allowing for more flexibility in the compressor's placement. For example, the 'Porter-Cable PCFP02003' features a 6-foot power cord that gives you the freedom to position the compressor in various locations. Another option is the 'California Air Tools CAT-1P1060SP', which comes equipped with a 8-foot power cord, ensuring ease of use even in areas where power outlets may be a bit farther away. Remember, a longer power cord can make your job smoother and eliminate the need for extension cords, providing added convenience during operation.

Control features: manual, automatic, programmable options

Control features encompass various options including manual, automatic, and programmable settings that allow you to adjust the compressor's performance based on your specific requirements.

For instance, the Bostitch BTFP02012 6 Gallon Pancake Compressor offers a manual control feature that gives you complete control over the compressor's operation. This is beneficial for users who prefer hands-on control and want to make real-time adjustments as needed.

On the other hand, the California Air Tools 10020C Ultra Quiet Air Compressor provides an automatic control feature, allowing the compressor to regulate its own operation based on the air demand. This eliminates the need for constant monitoring and adjustment, making it ideal for those who prefer a hassle-free experience.

Additionally, some compressors like the Makita MAC2400 Big Bore 2.5 HP Air Compressor offer programmable options. This allows you to set specific parameters such as desired pressure levels or duration for the compressor to turn on or off automatically. These programmable features are especially useful for repetitive tasks or applications that require a consistent air supply.

Understanding the control features of compressors is important in order to choose the right one that aligns with your preferences and usage requirements.

Backup or redundant systems: ability to switch between compressors

Some products that offer this feature include the Ingersoll Rand 2545E10-VP, Quincy QP-10, and Atlas Copco GA22FF. These types of compressors are equipped with advanced control panels that enable automatic or manual switching between multiple compressors, ensuring uninterrupted air supply in case of component failure or scheduled maintenance.

The Ingersoll Rand 2545E10-VP is an example of a compressor with dual control, meaning it can operate with just half of its compressors while the other half is being serviced. It features a dual receiver tank system and an IntelliDrive relying on a VSD air compressor to deliver superior energy efficiency and consistent air pressure. The Quincy QP-10 offers a redundant control system, allowing the unit to restart automatically from a remote location in case of an electricity supply failure. It also boasts a low oil carryover rate, ensuring high-quality compressed air. Lastly, the Atlas Copco GA22FF features a built-in priority control system that automatically switches to another compressor without manually readjusting the settings, guaranteeing reliable operation. These compressors serve as excellent examples of reliable backup or redundant systems for seamless switching and uninterrupted air supply.

Mobility features: wheels, handles for easy transportation

These features allow for effortless movement and convenient portability, making it simpler to transport the compressor from one location to another. When it comes to portable compressors with excellent mobility features, several options stand out. California Air Tools CAT-1P1060SP, with its lightweight design and sturdy handle, is a great choice for smaller projects and offers convenient portability. Another option is the Makita MAC5200 Big Bore 3.0 HP Air Compressor, which not only features durable wheels but also has a folding handle for easy storage and transportation. For larger projects and heavy-duty usage, the Rolair VT25BIG with pneumatic tires and a foldable handle is highly recommended. These compressors provide excellent mobility features that greatly enhance convenience and ease of use.

Hybrid capabilities: dual fuel options

Dual fuel compressors provide the flexibility of operating with either gasoline or propane, allowing users to choose the fuel that best suits their needs. One example of a compressor with hybrid capabilities is the CAT-1P1060SP from California Air Tools. This portable, oil-free compressor has a 1.0-gallon tank and a 0.6 HP motor, making it suitable for small tasks. It offers a dual power option, enabling users to switch between gasoline and propane fuel sources.

Another product to consider is the DEWALT DXCMLA1983012 compressor, which also features hybrid capabilities. This powerful compressor has a 30-gallon tank and a 1.9 HP motor, making it ideal for larger tasks. With its dual fuel capability, it provides the convenience of using either gasoline or propane as the power source, catering to different applications and fuel availability.

Price

Compressors are available in a wide price range, catering to different needs and budgets. For those on a tight budget, the BOSTITCH Pancake Air Compressor is an excellent option, priced at under $100. It offers a maximum pressure of 150 PSI and boasts a 6-gallon tank, making it ideal for small DIY projects. Another affordable choice is the PORTER-CABLE C2002-WK Oil-Free UMC Pancake Compressor Kit, priced just above $100. This kit includes 13 different accessories, making it convenient for various tasks. In the mid-price range, the Makita MAC2400 Big Bore Air Compressor is a popular choice, priced around $300. With its durable 2.5 HP motor and cast iron pump, it provides smooth operation and enhanced longevity for professional use.

Variety of brands

Different brands offer different features and quality levels, so it's important to research and compare before making a decision.

For example, Ingersoll Rand is a well-known brand in the compressor industry that offers a wide range of models suitable for various applications. Their compressors are known for their durability and high performance. One popular model is the Ingersoll Rand SS3F2-GM Garage Mate 15 Amp 2 HP 30 Gallon Single Phase Compressor, which features a 100% continuous duty cycle and a maximum pressure of 135 psi.

On the other hand, California Air Tools is praised for their ultra-quiet operations in comparison to many other compressor brands. Their models, such as the California Air Tools CAT-1P1060S Light & Quiet Portable Air Compressor, have noise levels as low as 56 decibels. These compressors are ideal for environments where noise reduction is crucial.

The market also offers a variety of niche brands that cater to specific needs. For example, DeWalt is well-regarded for their portable compressors, such as the DeWalt DWFP55130 Heavy Duty 200 PSI Quiet Trim Compressor that offers high performance in a compact design. Makita, a popular brand in the construction industry, provides durable compressors like the Makita MAC2400 Big Bore 2.5 HP Air Compressor that deliver high output and quick recovery time.

Ultimately, when choosing a compressor, it is important to carefully consider the pros and cons of different brands and models based on your specific needs and preferences.