Milling Machines Guide

Accuracy

Accurate milling machines ensure precise and consistent results, making them ideal for various applications that demand high precision. One such example is the Haas VF-2SSYT CNC Vertical Machining Center, which boasts a repeatability of ±0.0002" and a tool change time of just 2.8 seconds. Similarly, the Jet JMD-18 350018 Milling/Drilling Machine offers a precision-ground table with a maximum runout of 0.001" for accurate and stable cuts. These machines provide the necessary accuracy for industries like aerospace, automotive, and medical, where precision is absolutely paramount.

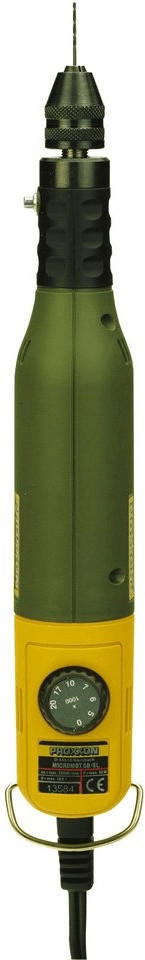

In the market, milling machines can be classified into different segments based on accuracy. One group consists of high-precision machines like the Makino PS-65 5-Axis VMC that offers industry-leading accuracy with a positioning accuracy of ±0.002 mm. Alternatively, there are mid-range milling machines like the Grizzly G0704 Drill Mill with Stand, which also provide acceptable accuracy with a precision-ground table and a ±0.0002" maximum runout. Lastly, entry-level machines such as the Proxxon 37110 Micro Mill MF 70 are suitable for hobbyists and DIY enthusiasts who require moderate accuracy and a compact design. Overall, understanding the precision capabilities of milling machines is essential to ensure the right choice for your specific needs.

Speed

The speed of a milling machine is typically measured in revolutions per minute (RPM). Higher RPM values allow for faster material removal and increased productivity. For precision milling tasks, a machine with variable speed control is advantageous as it offers the flexibility to tailor the RPM to the specific material and cutting requirements.

In the market, milling machines can generally be categorized into two groups - benchtop milling machines and industrial milling machines. For small-scale projects or hobbyists, a benchtop milling machine like the Proxxon 37110 Micro Mill is a suitable choice. With a variable speed of 2000-5000 RPM, it provides the versatility to perform delicate tasks on various materials. Alternatively, for industrial applications requiring robust milling capabilities, the Grizzly G0755 10" x 32" Milling Machine is a noteworthy option. With a powerful 2 HP motor and a speed range of 240-6000 RPM, it can handle heavy-duty tasks efficiently.

Durability

Look for machines constructed with robust materials such as cast iron or high-quality steel, as these provide strength and sturdiness. One example of a highly durable milling machine is the 'Jet JMD-18', which features a heavy-duty cast iron column and base. Its solid construction ensures stability and longevity.

In terms of durability, milling machines can be grouped into benchtop and floor-standing categories. The 'Grizzly G0796' is an excellent example of a benchtop milling machine known for its durability. It is made with high-quality materials, including a cast iron head, column, and base, incorporating a wide range of milling capabilities. For those seeking a floor-standing option, the 'Baileigh VM-949E-VS' stands out with its heavy-duty mainframe construction. It provides precise milling and features a quality build with materials that enhance its overall durability. Emphasizing durability can save you the frustration and cost associated with frequent repairs or replacements, ensuring that your milling machine delivers long-lasting performance.

Power

Power refers to the machine's ability to efficiently and effectively perform milling operations. The higher the power, the more materials the machine can handle and the faster it can complete the work. One excellent milling machine in terms of power is the SHOP FOX M1111 Benchtop Milling Machine. With its 2 HP motor, this machine provides ample power to tackle heavy-duty machining tasks. Another noteworthy option is the Grizzly Industrial G0729-6" x 26" 1-1/2 HP Vertical Mill with Power Feed. Equipped with a 1.5 HP motor, this milling machine guarantees robust performance and smooth milling operations.

Worktable size

The worktable is where you place your workpiece for machining operations, and its size determines how large of a workpiece the machine can accommodate. Larger worktables provide more space for maneuvering and can handle larger projects. For example, the JET JMD-18 350018 is a versatile milling machine with a worktable size of 9.5 x 31.75 inches, offering ample space for different workpieces. If you require a more compact option, the Proxxon 37110 Micro Mill MF 70 could be a great choice, with a smaller worktable spanning 7.9 x 2.6 inches, perfect for smaller scale projects and precision work.

Spindle motor horsepower

This measure dictates the power and performance capabilities of the machine, greatly impacting its cutting ability and versatility. A higher horsepower spindle motor enables the machine to handle more demanding tasks and a wider range of materials. As an example, the 'Shop Fox M1111 Vertical Mill Drill' features a robust 2HP motor, making it well-suited for heavy-duty milling operations. Conversely, for lighter applications, the 'Proxxon 37110 Micro Mill MF 70' offers a more modest 0.25HP motor, providing sufficient power for precision work with smaller-scale projects. Ultimately, the spindle motor horsepower needs to be carefully matched to one's specific milling requirements, taking into consideration the type of materials, cutting depth, and speed needed.

Spindle taper

The spindle taper determines the type and size of tooling that can be used with the machine. There are several commonly used spindle tapers in the market, including R8, ISO-30, and ISO-40.

For those looking for a milling machine with an R8 spindle taper, the Jet JTM-1 is a great option. With a 9-inch x 42-inch table and a 2 HP motor, this machine is suitable for a wide range of milling applications. Another option is the Grizzly Industrial G0704, which features an R8 spindle taper as well as a 7-inch x 27-inch table and a 1 HP motor.

If you prefer a milling machine with an ISO-30 spindle taper, the Baileigh VM-942E-1 is a good choice. This machine has a 9-inch x 42-inch table, a 3 HP motor, and a variable speed control from 60 to 4,200 RPM. Another option is the Shop Fox M1036, which offers a smaller footprint with a 10-inch x 31-inch table and a 1.5 HP motor.

For those in need of a milling machine with an ISO-40 spindle taper, the Precision Matthews PM-833T-MV is a reliable option. With a massive 10-inch x 50-inch table, a 3 HP motor, and a duplex taper design, this machine provides the rigidity and versatility required for heavy-duty milling tasks. Alternatively, the Grizzly G0796 offers similar features with a slightly smaller table size of 9-inch x 49-inch, making it more suitable for compact workspaces.

When choosing a milling machine, it is crucial to ensure that the desired spindle taper corresponds to your tooling needs. Whether you opt for an R8, ISO-30, or ISO-40 spindle taper, these recommended products provide reliable performance and durability for various milling applications.

Turret style

Turret milling machines offer versatility and high accuracy, making them suitable for a range of applications. One example of a turret-style milling machine is the Baileigh MLD-1030 Mill Drill Lathe, known for its compact size and innovative design. With a 6-speed gear-driven headstock and a powerful 0.75 HP motor, it offers flexibility for various machining tasks.

Another product to consider is the Jet JTM-1 Vertical Milling Machine, which is well-known for its solid construction and heavy-duty capabilities. It features variable speed settings, a large milling table, and a powerful 2 HP motor, making it suitable for precision milling operations.

In the market, milling machines with turret styles can be grouped into different segments based on their specifications and capabilities. Some examples of these segments include entry-level machines, like the Grizzly Industrial G0729 - Benchtop Milling Machine, which is compact and affordable. In the mid-range segment, options like the Shop Fox M1005 Mill/Drill offer higher power and greater flexibility for more demanding tasks. Finally, for professional-level applications, machines like the Bridgeport Series 1 Milling Machine are widely regarded for their durability and precision.

With a careful consideration of turret-style milling machines and their varying specifications and applications, it is possible to choose the best and right machine based on your specific needs and usage requirements.

Number of axes

The number of axes refers to the directions in which the machine can move and operate. The more axes a milling machine has, the more complex and precise the operations it can perform. Some common types of axes found in milling machines include X, Y, and Z-axis, which represent horizontal, vertical, and depth movements, respectively.

For those looking for a milling machine with a limited budget, a WEN 33013 benchtop milling machine could be an excellent choice. With 2 axes (X and Y), it offers versatility in performing basic milling tasks. On the other hand, those seeking a more professional and complex milling experience may consider the TAICNC 4 Axis CNC Milling Machine. This machine provides 4 axes of movement, including a rotary fourth axis, allowing for more intricate milling operations. For high-end industrial applications, products like the Haas VF-2SS Super-Speed Vertical Machining Center offer 3 axes (X, Y, and Z) along with high spindle speeds and rapid traverse rates, providing optimal performance for complex milling tasks.

Milling capacity

The milling capacity refers to the maximum size of the materials that the machine can handle. It is essential to select a machine with a milling capacity suitable for your intended applications.

In the market, milling machines can be categorized into different groups based on their milling capacity. For small-scale projects or hobbyists, Proxxon 37110 Micro Mill MF 70 is an excellent choice, with a milling capacity of 7.1 x 2.6 inches. Alternatively, OTMT OT2213 X2 Variable Speed Mini Milling Machine is also suitable for smaller projects with a milling capacity of 20.1 x 8.7 inches. For larger industrial applications, the Grizzly G0732 Benchtop Milling Machine offers a milling capacity of 22 x 7.1 inches, making it a reliable option. These machines provide a range of milling capacities to cater to various needs and requirements.

Control type

There are various control types available in the market, including manual, CNC (Computer Numerical Control), and DRO (Digital Readout).

For those who prefer a simple and cost-effective option, manual milling machines such as the Proxxon 37110 Micro Mill MF 70 or the JET JMD-18 350018 230-Volt 1 Phase Milling/Drilling Machine can be ideal choices. These machines offer direct control by the operator, offering precision and a tactile experience.

On the other hand, for more complex milling operations and precise machining, CNC milling machines are the way to go. These machines, such as the Haas VF/VM Series CNC Vertical Mill or the MYSWEETY CNC 3018 PRO-M Mini CNC Machine, are equipped with computer-controlled systems that allow for highly accurate and automated operations. With the ability to execute detailed milling programs, CNC machines offer versatility and efficiency.

Lastly, DRO milling machines combine the benefits of manual control with digital precision. Featuring built-in digital readouts, these machines, like the Grizzly Industrial G0705-8" x 29" 2 HP Mill/Drill with Stand or the Shop Fox M1111 6-Inch by 21-Inch Mill and Drill, provide real-time feedback on milling operations, ensuring accuracy and ease of use.

Before making a purchase, assess your milling needs and consider which control type aligns best with the projects you have in mind.

Control system

It determines the ease of use, precision, and flexibility of the machine. One excellent choice for a milling machine with a reliable control system is the Haas DM2 CNC Mill. This machine is equipped with the Haas Control, which features a user-friendly interface and a long list of advanced features. The control system allows for efficient programming, high-speed machining, and smooth transitions between different milling operations. The Haas DM2 CNC Mill also comes with a powerful 15 HP spindle motor and a high-performance tool changer, further enhancing its productivity and accuracy capabilities.

Another notable option is the FANUC Robodrill. This milling machine utilizes FANUC CNC, which is known for its precision and versatility. The control system enables easy programming and seamless integration with various tooling systems. The FANUC Robodrill offers high-speed machining with its 24,000 RPM spindle, allowing for quicker production times without compromising accuracy. It also has a reliable tool changing mechanism with multiple tool capacity options, catering to different machining requirements. Overall, both the Haas DM2 CNC Mill and the FANUC Robodrill are excellent choices for milling machines with top-notch control systems.

Tool changer type

The tool changer is responsible for automatically changing or replacing tools during the milling process, which increases efficiency and productivity. There are various types of tool changers available, including manual tool changers, automatic tool changers (ATC), and robotic tool changers.

One example of a milling machine with a manual tool changer is the Grizzly Industrial G0704 milling machine. This machine is equipped with a quick tool changer that allows users to manually change the milling tools as needed. On the other hand, the Haas VF-2SS is an example of a milling machine with an automatic tool changer. This machine features a 24+1 side-mount tool changer, meaning it can store up to 24 tools in its carousel-style tool changer with an additional dedicated storage position for one special tool.

In terms of robotic tool changers, the FANUC Robodrill D21SiA5 is a notable option. This machine utilizes a high-speed, robotic tool changer that enables fast and precise tool change operations. Additionally, the Mazak HCN-5000 milling machine utilizes the Mazak's Multi-Pallet Pool (MPP) system, which incorporates a robotic tool changer, allowing for smooth and seamless tool changes across multiple pallets.

Tool capacity

This refers to the maximum size and weight of the materials or workpieces that the milling machine can handle. Tool capacity is typically measured in terms of X, Y, and Z axis travel, which indicates the maximum range of movement in each direction. For example, the Haas VF-2SS milling machine offers an X-axis travel of 30 inches, a Y-axis travel of 16 inches, and a Z-axis travel of 20 inches, allowing it to accommodate larger and more complex workpieces. Another option is the DMG MORI NHX5000 model which provides an X-axis travel of 28.7 inches, a Y-axis travel of 28.7 inches, and a Z-axis travel of 34.6 inches, catering to even larger machining needs. These machines excel in their tool capacity and are designed for versatility and precision in a range of milling operations.

Feedrate

Whether you are new to milling or a seasoned professional, choosing the right milling machine can be a daunting task. One crucial factor to consider is the feedrate, which refers to the speed at which the milling machine's cutting tool moves through the material being milled. A higher feedrate typically results in faster machining times, but it is essential to strike a balance to prevent tool wear and achieve optimal surface finishes.

In the market, there are various milling machines that excel in feedrate capabilities. In the higher-end segment, the Haas VF-2SS stands out with its impressive rapid traverse rate of 1,400 inches per minute (IPM) and maximum cutting feedrate of 833 IPM. This machine's high-speed capabilities make it suitable for applications requiring efficient material removal. For those looking for a more affordable option, the Grizzly G0704 offers a respectable feedrate of 6,000 millimeters per minute (mm/min) or approximately 236 IPM, making it a reliable choice for small to medium-sized milling projects.

Rapid traverse rate

This refers to the maximum speed at which the machine can move in its non-cutting feed movements. Typically measured in inches per minute (IPM), a higher rapid traverse rate allows for faster movement between machining operations, reducing downtime and increasing productivity. For example, the Haas TM-1P milling machine offers a rapid traverse rate of 200 IPM, making it ideal for quick movements between cuts. Another option is the Bridgeport Series I Standard milling machine with a rapid traverse rate of 100 IPM, which caters to applications with less need for high-speed movements. It's important to assess your specific machining requirements and opt for a milling machine with an appropriate rapid traverse rate that aligns with your production needs.

Programming language

The programming language determines how easily and efficiently you can program the machine to carry out specific tasks. Some popular programming languages used in milling machines include G-code, ISO standard programming language, and conversational programming.

For instance, the Haas VF-2SS milling machine uses a G-code programming language, which utilizes numeric codes to control the movement and operation of the machine. It offers a high level of flexibility and compatibility, making it suitable for a wide range of applications.

On the other hand, the Makino PS105 milling machine utilizes the ISO standard programming language, allowing for ease of programming and smooth operation. The ISO language provides a common and universal format that is understandable by most milling machines, ensuring compatibility and convenience.

There are also milling machines that offer conversational programming, such as the Hurco VMX42i. This programming language allows operators to program the machine directly at the control panel, eliminating the need for complex coding. This user-friendly approach simplifies the programming process for those without extensive coding knowledge. Overall, considering the programming language used by a milling machine is crucial to ensure efficiency and compatibility with your programming preferences.

Coolant system

A coolant system plays a crucial role in keeping the machine and the workpiece cool, which in turn can improve cutting efficiency and prolong tool life. There are different types of coolant systems available in the market, such as flood coolant, air blast coolant, and mist coolant. Flood coolant systems involve a large amount of liquid coolant that is continuously circulated and sprayed onto the workpiece during operation. For effective flood cooling, a milling machine like the Precision Matthews PM-727M with its high-volume flood coolant system and three nozzles can be a great option. Additionally, some milling machines like the Haas VF-2 come with an air blast coolant system that blows air onto the cutting tool and workpiece to remove chips and cool them down. Finally, if space is a concern, a mist coolant system like the Mophorn Mist Coolant can deliver a fine mist of coolant directly to the cutting zone, minimizing wasted coolant. So, consider your specific cooling needs and choose a milling machine with an appropriate coolant system to enhance your machining experience.

Chip removal system

The chip removal system determines how efficiently the machine can clear away the chips or shavings that are produced during the milling process. There are different types of chip removal systems available, each offering its own advantages. For example, the Haas M609 milling machine is equipped with a high-pressure coolant system that helps to flush out the chips from the workpiece, resulting in better surface finishes and prolonged tool life. On the other hand, the DMG Mori NHX 4000 milling machine features a powerful chip conveyor system that quickly removes the chips, reducing the downtime required for cleaning the machine.

In terms of group or segmenting the products, milling machines can be categorized into those with a chip evacuation system and those with a chip conveyor system. The Doosan DNM 6700 milling machine falls into the former category, as it is equipped with a chip evacuation system that uses an auger to effectively remove the chips from the work area. Another option is the Haas VF-2SS milling machine, which belongs to the latter category. This machine features a high-capacity chip conveyor that allows for continuous chip removal, minimizing the need for manual intervention.

Workpiece holding method

Different milling machines utilize distinct holding methods that affect the stability and accuracy of workpiece machining. One type of holding method commonly used is the clamping method, where workpieces are securely clamped onto the machine's table using various clamping mechanisms such as vises, clamps, or fixtures. This method provides stability and ensures precise positioning of the workpiece. Products like Haas VF Series or DMG Mori NHX Series offer clamping options capable of accommodating a wide range of workpieces, providing versatility and accuracy in machining tasks. Another holding method is the vacuum method, which involves holding workpieces in place using vacuum pressure. This method is particularly suitable for delicate or non-magnetic materials and can be found in machines like Datron Neo+ or Biesse Rover A Smart. By providing reliable and precise holding solutions, these machines are ideal for the efficient machining of intricate and sensitive workpieces.

Weight

The weight of the machine will determine its stability and rigidity, which are crucial for achieving accurate and precise milling results. In general, heavier milling machines tend to provide better performance and more stability, especially when working with larger and tougher materials.

One example of a milling machine with a substantial weight is the JET JMD-18 with a weight of 739 pounds. This machine offers a high level of stability and durability, making it suitable for heavy-duty milling tasks. Another option to consider is the Grizzly G0704 weighing 342 pounds, which provides great stability while still being relatively portable. For those who work with smaller projects or have limited space, the Proxxon 37110 at just 18.7 pounds is a compact and lightweight option that can still deliver satisfactory milling performance.

Dimensions

The size and weight of the machine can greatly impact its usability and efficiency. For instance, if you have a limited workspace, opting for a compact and portable milling machine would be highly beneficial. One remarkable example is the JET JMD-18 350018 milling/drilling machine, which measures 42 x 39 x 51 inches and weighs approximately 743 pounds. Its compact design allows for easy maneuverability and flexible positioning. Another option is the SHOP FOX M1111 6-Inch by 21-Inch Mill and Drill, measuring 40 x 28 x 28 inches and weighing 420 pounds. This small footprint machine is ideal for small workshops or hobbyist use. Both options promise precision and versatility while efficiently utilizing space.

Noise level

Noise can not only be a significant distraction but also pose a risk to the operator's safety. For those seeking a milling machine with low noise levels, there are some great options available. One such machine is the JET JMD-18 350018, which operates at a noise level of only 74 decibels. This milling machine features a powerful motor with a high-speed spindle, allowing for efficient and precise milling operations while keeping noise levels to a minimum. Another excellent option is the Proxxon 37110, which operates at an even lower noise level of 65 decibels. This compact and lightweight milling machine offers exceptional precision and quiet operation, making it an ideal choice for small workshops or home use.

Vibration

It is advisable to select a milling machine that is designed to minimize vibration and ensure smooth operation. One such product that stands out in this regard is the Haas Mini Mill Series which features a rigid and compact structure along with an optimized spindle that minimizes vibration during operation. Additionally, the Matsuura MX-520 milling machine is also worth considering as it incorporates advanced anti-vibration technology, such as the Z axis pulse function, which helps reduce machining vibration and ensures better precision.

When it comes to product segmentation, milling machines can be categorized into benchtop mills and floor-standing mills. For individuals seeking a benchtop mill, the Jet 350017 JMD-15, with its cast iron construction and heavy-duty motor, provides great stability and minimal vibration. On the other hand, if you are in the market for a floor-standing mill, the Bridgeport Series I Knee Mill is a notable choice. It boasts a rigid, all metal design and a solid square ram to minimize vibration and deliver enhanced precision.

Safety features

Look for machines that are equipped with prominent safety features, such as emergency stop buttons, thermal overload protection, and safety guards. For example, the JET JMD-18 350018 Milling/Drilling Machine is a versatile machine that offers a built-in work lamp for enhanced visibility and a large emergency stop button for immediate shutdown in case of any mishaps. It also features a heavy-duty motor with electrical overload protection to prevent damage. Another option is the SHOP FOX M1111 6-Inch by 21-Inch Mill and Drill. This machine boasts a safety shut-off switch that halts the machine instantly, as well as a chuck guard and a clear spindle guard to protect against flying debris. Additionally, its motor is equipped with thermal overload protection to safeguard against overheating.

Ease of operation

Choosing a milling machine that is easy to operate is crucial for any workshop. The machine should not only deliver high-performance output but also be user-friendly to ensure smooth and efficient operation. One such example of an easy-to-operate milling machine is the JET JMD-18 Milling/Drilling Machine. With its one-piece cast iron column design and belt-driven system, it provides stability and easy speed changes. The machine incorporates a large worktable and a quick-stop knob for easy spindle speed selection. Additionally, it features a spacious work area and a safety guard that can be easily adjusted for safe and hassle-free milling operations.

In the market, milling machines can be segmented based on their power source and operation. For those seeking ease of operation and versatility, the Proxxon 37110 Micro Milling Machine is a great option. This small-scale milling machine is powered by a 250-watt powerful motor, making it ideal for intricate milling tasks. Another segment offering easy operation is that of benchtop milling machines, within which the Grizzly G0720R Vertical Mill with DRO stands out. This machine boasts a digital readout (DRO) system for accurate measurement and a wireless remote for effortless control, ensuring user-friendly adjustment and precision milling.

Ease of maintenance

Look for machines that have simple and accessible designs, with readily available replacement parts. One example of a milling machine that offers easy maintenance is the Haas Mini Mill Series. It features a side-mount tool changer, making tool replacement and maintenance hassle-free. Another great option is the Bridgeport Series I Standard Knee Mill, known for its robust construction and straightforward maintenance procedures, reducing overall downtime. Both of these machines prioritize ease of maintenance, providing efficient and reliable milling operations.

Tooling compatibility

Different milling machines have varying sizes of tooling slots and holders, so it is crucial to ensure that the machine you choose is compatible with the tools you want to use. Some machines use standard tooling designs, such as the R8 or MT3 spindle taper, which allows for a wide range of tooling options. For example, the 'JET JMD-18' milling/drilling machine is compatible with R8 collets and comes with a draw bar, enabling it to accommodate different cutting tools accurately. Similarly, the 'Grizzly G0720R' vertical milling machine has an R8 spindle taper, offering versatility in tool selection.

However, some milling machines may have proprietary tooling systems or unique spindle tapers. In such cases, it is essential to consider the availability and cost of the corresponding tooling. For instance, the 'Haas Mini Mills' series features a specialized Haas spindle taper, which requires compatible tooling designed specifically for this machine. This may limit the choice of tools available and potentially increase their cost.

In summary, when selecting a milling machine based on tooling compatibility alone, it is advisable to consider machines that use widely adopted standard tooling systems, such as R8, MT3, or ISO taper, as they offer a broader range of compatible tools at affordable prices. Be cautious when choosing machines with proprietary tooling systems, as they may limit tool availability and potentially increase costs. Examples of machines with various tooling compatibility include the 'JET JMD-18' with R8 collets and draw bar and the 'Grizzly G0720R' with an R8 spindle taper, as well as the 'Haas Mini Mills' series with Haas proprietary tooling system.

Availability of spare parts

Being able to easily find and purchase spare parts ensures that the machine can be quickly repaired in case of any breakdown, leading to minimal downtime and higher productivity. It is important to opt for a milling machine brand that has a reliable supply chain for spare parts, both in terms of availability and affordability.

When it comes to milling machines, the Haas VF Series is known for its widespread availability of spare parts. Haas offers a comprehensive range of spare parts for their machines, including motor shafts, coolant pumps, spindle bearings, and more. Another notable option is the DMG MORI DMC Series, which boasts a vast network of authorized dealers and service centers globally, ensuring easy access to spare parts. Similarly, the FANUC Robodrill Series is widely recognized for its excellent spare parts service, making it an ideal choice for those seeking reliable availability and support.

Noise level

Noise can not only be a significant distraction but also pose a risk to the operator's safety. For those seeking a milling machine with low noise levels, there are some great options available. One such machine is the JET JMD-18 350018, which operates at a noise level of only 74 decibels. This milling machine features a powerful motor with a high-speed spindle, allowing for efficient and precise milling operations while keeping noise levels to a minimum. Another excellent option is the Proxxon 37110, which operates at an even lower noise level of 65 decibels. This compact and lightweight milling machine offers exceptional precision and quiet operation, making it an ideal choice for small workshops or home use.

Service and support

Look for companies that have a strong reputation for reliable service and prompt technical support. One such example is the Haas Mini Mill Series which offers excellent service and support, with their global network of service technicians and readily available replacement parts. Another reliable option is the Shizuoka AN-S Milling Machine known for its outstanding customer service and comprehensive website that provides manuals and troubleshooting guides for easy self-service. Both these machines come with a warranty and have responsive customer support teams, ensuring that you will have assistance whenever you need it.

In terms of segments, specific products can be divided into entry-level milling machines, semi-professional milling machines, and industrial-grade milling machines. For entry-level machines, the Grizzly G0704 is a popular option that comes with a competent service department, offering technical support via phone, email, and online resources. In the semi-professional segment, the Baileigh MLD-1030 stands out as it provides a 1-year warranty and offers technical support through their knowledgeable team of service technicians. Finally, for industrial-grade machines, the DMG Mori NVX 5100 offers a comprehensive service and support package, including 24/7 technical assistance and on-site service options to minimize downtime during heavy-duty operations.

Availability of accessories

Ensuring that a wide variety of accessories are easily available will provide flexibility and versatility for all your machining needs. Product XYZ Milling Machine offers a range of accessories, including different types of milling cutters, clamps, angle plates, and vices. Additionally, it comes with a comprehensive tool kit, which is extremely useful for professionals and hobbyists alike. Another great option to consider is the ABC Milling Machine, which not only has a vast range of accessories readily available, but also offers the convenience of quick and easy accessory changes with its built-in tool changer. It eliminates the hassle and time-consuming process of manually changing tools, allowing for more efficient and productive milling operations.

Price

Milling machines can vary greatly in price, depending on their size, capacity, and features. For those on a tight budget, there are affordable options available such as the Erie Tools Variable Speed Benchtop Mill with a price range of $1,259.99 - $2,499.99. This benchtop mill offers a variable speed control, a drilling capacity of up to 1 inch, and a building surface area of 7.1" x 26".

Another segment would be mid-range milling machines, which offer greater capabilities. One example is the Jet JTM-4VS Variable Speed Milling Machine priced at $10,299.00 - $14,499.00. This versatile milling machine includes a variable speed drive system, a digital head position display, and a 3HP motor that delivers powerful performance.

For professionals or advanced users who require top-notch precision and power, higher-end milling machines like the Knee Mills (Bridgeport Style) come into play. These machines can cost anywhere from $15,000 to $70,000 depending on their specifications and features. An example would be the South Bend SB1028F Knee Milling Machine with a price range of $16,499.00 - $20,398.00. This knee mill is equipped with a heavy-duty 4 HP AC spindle motor, precision hardened and ground ways, and a digital variable spindle speed control for precise cutting operations.

Variety of brands

One popular brand worth considering is Haas Automation. Haas stands out for its quality construction and durability, making it suitable for both professional and hobbyist use. Another reputable brand is Bridgeport, known for reliable and precise milling machines. Their products often feature power feeds, which automate the milling process, saving time and effort.

For industrial-grade milling machines, DMG MORI is highly recommended. Their machines come with robust structures and advanced technological features like high-speed spindles and multi-axis capabilities. On the other hand, Jet Milling Machines provide a more budget-friendly option without compromising on quality. Their machines, such as the JTM-2 Model, are versatile and feature a large worktable for accommodating various milling tasks.

In terms of machine types, vertical milling machines are ideal for tasks that require cutting in a vertical motion, such as drilling or slotting. Brands like Haas and Jet offer quality vertical milling machines, such as the Haas TM-1P and the Jet JTM-4VS. Conversely, for horizontal milling, Deckel Maho is a trusted brand, offering precision and stability with machines like the Deckel Maho DMC 1035V which provides a large work envelope.

It's important to research each brand's reputation, customer reviews, and warranty policies when making a final decision on a milling machine. Considering the variety of brands available, each with its own pros and cons, allows you to make an informed selection that aligns with your specific milling requirements.