Saw Blades Guide

Blade Type

Different blade types are designed for specific cutting applications and materials. One of the most common blade types is the general-purpose crosscut saw blade. These blades are versatile and suitable for cutting through a variety of materials, including wood, plywood, and plastic. They typically feature a high-carbon steel construction and have fine teeth that produce clean and smooth cuts. Examples of general-purpose crosscut saw blades include the Freud D0760A Diablo 60-Tooth ATB Fine Finish Saw Blade and the DEWALT DW3128P5 OptiPith Circular Saw Blade with 12- and 80-tooth, respectively.

Another popular blade type is the ripping blade, which is tailored for cutting along the grain of the wood. These blades typically feature a lower tooth count and large gullets, allowing for fast and efficient material removal. One example of a ripping blade is the Freud D0624X Diablo 24-Tooth ATB Carbodyde Framing Ripping Saw Blade, which is specifically designed for ripping and crosscutting wood and composite materials.

Additionally, there are specialty blades available for specific cutting tasks. For instance, the Bosch DB1066C Daredevil Framing Blade is a specialty blade specifically designed for heavy-duty demolition work, such as cutting through nails and other embedded materials in framing applications. The DB1066C features 6 TPI (teeth per inch) and a reinforced shoulder, ensuring durability and longevity.

Considering the blade type is crucial as it directly impacts the effectiveness and quality of your cuts. Properly assessing your cutting requirements and selecting a blade designed to excel in those conditions is essential for achieving optimal results.

Blade Thickness

The thickness of the blade can impact the durability, precision, and cutting speed of the saw. Thicker blades tend to be more stable and can reduce the risk of warping or bending during use. On the other hand, thinner blades can provide a smooth and precise cut, making them ideal for projects that require precision.

In the market, saw blades are available in various thicknesses suiting different needs. For applications that require durability and stability, the Freud Diablo D1080N 10-Inch 80 Tooth TCG Non-Ferrous Metal and Plastic Cutting Circular Saw Blade with 0.094-inch thickness proves to be a reliable choice. Alternatively, for projects that prioritize precision, the Bosch DCB624 Daredevil 24T Circular Saw Blade with a thin 0.039-inch kerf provides exceptional precision and smooth cutting, making it suitable for delicate woodworking tasks. Both of these examples highlight how blade thickness can impact performance in different types of projects.

Blade Material

The material of the blade determines its durability and cutting performance. There are various types of blade materials available on the market, each suitable for different cutting tasks.

Carbide tipped blades are known for their excellent cutting performance and extended lifespan. The carbide tips are made from tungsten carbide, which is highly resistant to wear and can cut through even the hardest materials. A popular carbide tipped blade is the Freud D1080X Diablo, featuring a combination of high-density carbide and an ultra-sharp cutting edge for smooth and clean cuts.

Another frequently used blade material is high-speed steel (HSS), which is renowned for its heat resistance. HSS blades can consistently handle high speeds without losing their cutting edge. A trusted brand in the HSS field is DeWalt, offering blades such as the DeWalt DW3128P5 which utilizes carbide teeth combined with a tough steel body for enhanced durability.

Additionally, some saw blades are constructed from bi-metal, a combination of high-speed steel teeth and a flexible spring steel body. Bi-metal blades are specifically designed for heavy-duty cutting tasks, providing superior performance and longer overall life. An excellent bi-metal blade is the Milwaukee 49-22-1145 with its array of bi-metal teeth specifically engineered to withstand intensive cutting.

These are just a few examples of saw blades available in the market, each specifically designed to meet different cutting needs based on the material chosen for its construction. By considering the blade material, you can effectively select a blade that will provide optimal cutting results and durability for your specific application.

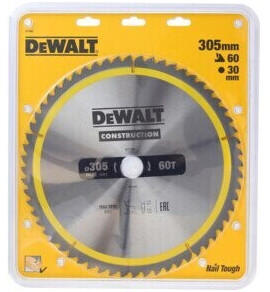

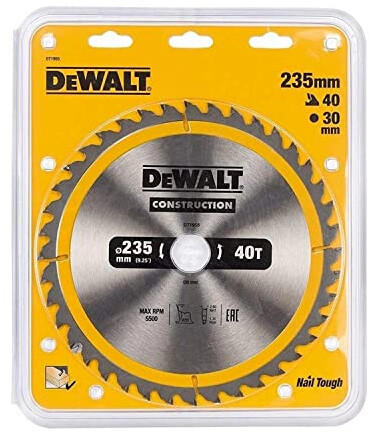

Blade Tooth Count

The tooth count determines how smooth and clean the cuts will be. Blades with a higher tooth count provide finer and smoother cuts, making them ideal for tasks that require precision and a polished finish, such as cutting through delicate materials like plywood or melamine. On the other hand, blades with a lower tooth count are better suited for tasks that require fast and rough cuts, such as cutting through softwoods or framing materials.

For those in need of a saw blade with a higher tooth count, the Freud D1060X is a reliable option. With its 60-tooth design, this crosscutting blade provides excellent finish quality without sacrificing speed. It features Tri-Metal Brazing, anti-vibration technology, and Perma-Shield Non-Stick Coating, ensuring excellent performance and longevity. Alternatively, for those looking for a lower tooth count blade, the Diablo Demo Demon is a suitable choice with its 24-tooth configuration. This ultra-coarse blade is designed for rough cutting and demolition work, featuring Carbide teeth that can withstand challenging applications. Overall, matching the appropriate tooth count to your cutting needs is crucial to achieve the desired results.

Blade Diameter

The blade diameter refers to the size of the circular blade and plays a crucial role in determining the type of cut you can make and the speed at which you can cut through materials. Typically, the larger the blade diameter, the deeper the cut it can make. For example, the DEWALT DW738 10-Inch Circular Saw Blade has a diameter of 10 inches, making it suitable for making deep cuts in thick materials such as lumber. On the other hand, a smaller blade diameter like the Freud Diablo D0724A 7-1/4-Inch Circular Saw Blade is ideal for making precision cuts in thinner materials like plywood or MDF. It's important to choose a saw blade with a diameter that meets your specific cutting needs and the thickness of the material you will be working with.

Blade Arbor Size

The arbor size refers to the diameter of the hole in the center of the saw blade that fits onto the arbor of the saw. It is crucial to choose a saw blade with a matching arbor size to ensure a proper fit and safe operation.

Some popular saw blades with different arbor sizes include:

Diablo D1080X - This 10-inch saw blade features a standard 5/8-inch arbor size, making it compatible with most stationary table saws. It is renowned for its durability and ability to handle various materials, including hardwood, softwood, and even non-ferrous metals.

Freud D0740X- With a smaller 1/2-inch arbor size, this 7-1/4-inch saw blade is commonly used in circular saws, miter saws, and even some table saws. Its thin kerf design reduces cutting resistance while providing clean and precise cuts in different wood materials.Makita A-90451- Specializing in smooth cuts on plywood, this 14-inch saw blade is designed with a metric bore size of 25.4mm. It is suitable for use with professional-grade sliding compound miter saws, delivering high-performance and long-lasting cutting performance.

Remember to always confirm the arbor size of your saw before purchasing a new blade to ensure compatibility and maximize the performance of your cutting tools.

Blade Hook Angle

The Blade Hook Angle refers to the angle at which the teeth of the blade tilt forward or backward in relation to the blade's centerline. A positive hook angle (+10 to +20 degrees) means the teeth tilt forward, resulting in aggressive cutting with a faster feed rate. This is ideal for ripping and crosscutting solid wood or plywood. For example, the Freud Diablo D0724PX is a saw blade with a positive hook angle of +15 degrees, making it suitable for fast and efficient cutting in woodworking projects.

On the other hand, a negative hook angle (-10 to -20 degrees) means the teeth tilt backward. This allows for smoother and slower cutting, reducing the risk of material tear-out. If you're working with delicate materials like laminates or melamine, a saw blade like the Forrest WW10407125 with a negative hook angle of -5 degrees would be a good choice. It provides clean and precise cuts, minimizing chip-out and leaving smooth edges. Remember to consider the type of material you'll be cutting and the desired cutting speed when selecting a saw blade with the appropriate hook angle.

Blade Kerf Width

The kerf width refers to the thickness of the cut made by the saw blade, and it is crucial in determining the precision and efficiency of your cuts.

For fine woodworking and intricate cutting tasks, you may want to look for blades with a narrow kerf width. These blades remove less material during the cut, resulting in finer and more precise cuts. One example of a saw blade with a narrow kerf width is theFreud LU79R010 Thin Kerf Ultimate Plywood & Melamine Saw Blade. With a kerf width of only 0.90mm, this blade is specially designed for cutting laminates and veneered plywood with minimal tear-out.

On the other hand, if you need to carry out tasks that require faster cutting speeds and less precision, a blade with a wider kerf width may be more suitable. A wider kerf width allows for larger removal of material, leading to quicker cuts. An option for a saw blade with a wider kerf width is the Diablo D1060CF Composite Trex Blade. With a kerf width of 2.36mm, this blade is perfect for cutting composite decking materials, providing efficient and rapid cuts.

Blade Grind Type

There are several grind types available, each offering distinct advantages for specific applications. For general purpose cutting and ripping, a flat top grind (FTG) blade is a popular choice. These blades, such as the Freud LU87R010 or the Diablo D1050X, have large, flat topped teeth that efficiently remove material, making them ideal for straight cuts in both hardwoods and softwoods. On the other hand, alternate top bevel (ATB) blades like the Freud Diablo D1050X or the DeWalt DW3106P5 have teeth with alternating angling bevels, providing smoother cuts in plywood, laminates, and cross-cutting tasks. Lastly, combination (COMB) blades are a versatile option that features groups of FTG teeth followed by groups of ATB teeth. They offer the benefits of both grind types, making them especially useful for cutting different materials such as hardwoods and plywood. Some well-regarded combination blades include the Forrest WW10407125 and the Freud LU86R010.

Blade Design/Shape

The blade design determines how the saw cuts through materials, and different designs are suited for different types of cuts. For example, a rip-cut blade is designed to cut along the grain of the wood and has fewer teeth with larger gullets to remove material quickly. A popular option in this category is the Diablo D1024X, which features a thin-kerf design for fast and easy cutting. On the other hand, a crosscut blade is designed to cut across the grain of the wood and has more teeth to create a smoother finish. A highly recommended crosscut blade is the Freud D12100X, which has 100 teeth for ultra-smooth cuts and is ideal for hardwoods, softwoods, and plywood. Lastly, there are combination blades that are versatile and can handle both rip and crosscutting tasks, such as the Irwin Marathon 24030, which offers a triple-chip tooth grind for both ripping and crosscutting applications.

Blade Coating

The coating on a saw blade can greatly impact its performance and durability. There are various types of blade coatings available on the market, each offering unique benefits. For example, the Freud LU83R010 saw blade features a Perma-Shield coating that reduces friction and heat buildup, resulting in clean cuts and extended blade life. Another excellent option is the Diablo D1060X saw blade, known for its TiCo Hi-Density carbide coating that maximizes cutting performance and enhances overall durability. Lastly, the DEWALT DW3106P5 saw blade stands out with its Tough Coat anti-stick coating, minimizing friction and gumming up, allowing for smoother cuts and easy cleanup. These blades, equipped with top-notch coatings, will elevate your cutting experience significantly.

Blade Expansion Slots

Blade expansion slots help to reduce heat buildup and keep the blade cool during use, ensuring smooth cuts and extended blade life. One example of a saw blade with effective blade expansion slots is the DEWALT DW3106P5 10-Inch Saw Blade Set. It features expansion slots that are designed to reduce vibration and heat buildup, delivering clean and precise cuts. Another notable option is the Freud Diablo D0536X Finishing Saw Blade, which is equipped with ultra-sharp carbide teeth and laser-cut expansion slots for improved performance and durability. Both options demonstrate the significance of blade expansion slots in achieving optimal results while using saw blades.

Blade TPI (Teeth per Inch)

This measurement determines the speed and smoothness of the cut. Generally, blades with a low TPI, such as 4 TPI, are best suited for aggressive and fast cuts in materials like wood. On the other hand, blades with a high TPI, like 24 TPI, are ideal for finer and clean cuts on materials such as metal or plastic.

There are various saw blades available on the market, catering to different TPI requirements. For woodworking projects, blades like the Freud D1040X Diablo with 40 TPI offer a smooth finish and efficient cutting speed. For metal-cutting applications, the DEWALT DW4890 with 14 TPI offers fast and precise cuts. Different manufacturers produce blades with a range of TPI, allowing users to choose the most appropriate option for their specific needs.

Blade Tooth Shape

There are several different tooth shapes available, each designed for specific cutting applications. For general use, a crosscut tooth shape is ideal. It features beveled teeth that create clean, smooth cuts across the wood grain. A popular crosscut blade option is the Freud D12100X 100 Tooth- TCG with a 10-inch diameter.

On the other hand, if you primarily work with plywood or other veneered materials, a blade with an alternate top bevel (ATB) tooth shape is recommended. The ATB shape is specifically designed for cutting across the wood grain and reduces splintering on the top surface. A reliable ATB blade on the market is the Irwin Marathon 14070 10-Inch 24-Tooth ATB Ripping Saw Blade.

For more aggressive ripping cuts along the wood grain, a blade with a flat top grind (FTG) tooth shape is ideal. It has square teeth that cut through wood quickly and efficiently. An FTG blade to consider is the DeWalt DW7880 3/4-Inch 10 TPI Raker Tooth Scroll Saw Blade.

Lastly, if you work with various materials, including metal or plastic, a continuous rim cutting edge blade is crucial. This blade features a diamond grit edge for enhanced durability and precision. An excellent continuous rim cutting edge blade for tile, stone, and other abrasive materials is the Bosch DB543S 3-Inch Continuous Rim Diamond Blade.

Cutting Depth

The cutting depth refers to the maximum thickness of material that the saw blade can cut through in a single pass. This is particularly important for those who work with thick or dense materials.

In the market, different saw blades offer various cutting depths. For example, the 'Bosch DCB1280CB 12-Inch 80-Tooth Edge Circular Saw Blade' has a cutting depth of 2.75 inches, which makes it suitable for cutting through thicker stock. On the other hand, the 'Freud D1080X Diablo 10-Inch 80 Tooth Fine Finish Saw Blade' is designed for precise cuts with a cutting depth of 3 inches. Additionally, there are segmented blades that can be grouped into two categories based on cutting depth. The 'DEWALT DW4706 6-1/2-Inch Fast Cutting Segmented Diamond Circular Saw Blade' and the 'Makita A-94514 12" Segmented Diamond Saw Blade' both have a cutting depth of 1 inch and are ideal for masonry and concrete materials. Considering the cutting depth of a saw blade ensures that it will meet the requirements of your specific cutting needs.

Cutting Speed

It refers to the speed at which a blade cuts through a material, and this can vary depending on the type of saw and the material being cut. High cutting speeds are desirable for achieving efficient and clean cuts. For example, the 'Freud D0740A' circular saw blade offers a cutting speed of 6,000 RPM, making it ideal for fast and smooth cuts in various woods and plywood. Another option is the 'Diablo D0842CF' carbide tooth circular saw blade with a speed rating of 8,300 RPM, designed specifically for cutting composite decking materials with precision and speed. Additionally, segmented blades like the 'DEWALT DW4712B3' masonry saw blade offer a cutting speed of 6,600 RPM, making them suitable for cutting through brick and concrete quickly and efficiently. Therefore, considering the cutting speed of a saw blade is crucial to ensure optimal performance and productivity.

Cutting Accuracy

It determines the clean and precise finish of your cuts. One example of a saw blade known for its exceptional cutting accuracy is the Freud LU83R010 10-Inch Thin Kerf Rip Saw Blade. With 50 teeth and a super-thin kerf design, this blade delivers whisper-quiet cuts with minimal wastage. Another great option is the Diablo D1050CF 10-Inch Steel Demon Carbide Tipped Metal Cutting Saw Blade. Designed specifically for cutting metal, it features a thin laser-cut kerf for sharp and clean slicing. Its carbide teeth provide increased durability, ensuring accurate cuts on a variety of materials. Remember, precision saw blades like these not only enhance the quality of your work but can also save you time and effort in the long run.

Cutting Cleanliness

Cutting cleanliness ultimately refers to the quality of the cut and the smoothness of the finished surface. For tasks that require clean and precise cuts, such as woodworking or laminate flooring installation, it is crucial to opt for a saw blade that ensures minimal tear-out and produces a smooth surface.

One excellent example of a saw blade that excels in cutting cleanliness is the Freud LU79R009 Ultimate Plywood Cutting Saw Blade. This 10-inch blade is specifically designed for clean crosscuts in plywood. Featuring a unique tooth geometry with a hi-ATB (alternating top bevel) grind, the Freud LU79R009 minimizes chipping and splintering, resulting in smooth and clean cuts. Additionally, the blade has an anti-vibration design that further enhances the cutting cleanliness by reducing the potential for blade flex and tear-out.

In the segment of metal cutting blades, the DEWALT DW9153 Construction Series Circular Saw Blade stands out for its cutting cleanliness. With its high-grade carbide teeth that can withstand the demanding requirements of cutting metal, this blade offers clean, burr-free cuts with minimal spark generation. Its anti-stick rim reduces friction and gum-up, ensuring smooth operation, while its ultra-sharp cutting edges provide precise and clean results.

Cutting Efficiency

The cutting efficiency of a saw blade refers to its ability to cut through materials quickly and effortlessly. One example of a saw blade that excels in cutting efficiency is the Freud D1050X Diablo 10-Inch 50-tooth ATB Combination Saw Blade. This blade is specifically designed for precise crosscuts and rips in wood, thanks to its large number of teeth, which ensures fast and smooth cuts. Additionally, the Freud LU79R012 12-Inch 96 Tooth TCG Double Sided Laminate/Melamine Blade provides excellent cutting efficiency when working with laminates and melamine. Its triple-chip grind (TCG) and high tooth count maximize cutting speed and accuracy in these materials. Overall, both blades mentioned are excellent choices for different cutting tasks, with cutting efficiency being their standout feature.

Cutting Capacity

The cutting capacity of a saw blade refers to the maximum depth or thickness of material it can cut. This is an important consideration as it determines the range of tasks the blade is suitable for. For instance, if you frequently work with large or thick pieces of wood, you'll want to choose a saw blade with a higher cutting capacity, such as the 'DEWALT DW3106P5' 10" Combination Saw Blade Set that offers a cutting depth of up to 3-5/16 inches. On the other hand, if you primarily handle smaller and thinner materials, a saw blade with a lower cutting capacity like the 'Diablo D1050X' 10" Combination Saw Blade that can cut up to 2-7/8 inches thick should be sufficient. Different saw blades offer different cutting capacities, so it's crucial to consider this when selecting the right blade for your job.

Cutting Application

Different tasks require different types of blades, designed for optimal performance in specific materials and cutting methods. For example, if you are planning to cut through hardwood, a rip saw blade like the Freud LU97R010 Thin Kerf TCG Saw Blade would be suitable, as it is specifically engineered for ripping cuts in dense materials. On the other hand, for delicate and precise cuts in plywood or melamine, a crosscut blade such as the DEWALT DW3311 Crosscutting Saw Blade offers ultra-sharp teeth and a low tooth count to prevent tearing or chipping. For those in need of a blade versatile enough to handle a variety of materials, a combination blade like the Irwin Tools Marathon 24020 Circular Saw Blade is designed with both ripping and crosscutting in mind, providing clean cuts across different applications. Overall, understanding your cutting application is crucial in selecting the appropriate saw blade for optimal performance and efficiency.

Blade Durability

For instance, the 'Freud D1080X Diablo' is a popular choice known for its exceptional durability. It features high-density carbide tips that provide long blade life, while the laser-cut stabilizer vents reduce noise and vibration. Another notable product is the 'IRWIN Marathon with WeldTec', which boasts welded carbide teeth and controlled tension technology for enhanced durability and precise cuts. These products stand out for their prolonged lifespan and ability to withstand tough applications, making them great options when prioritizing blade durability.

Segmentation of blade products based on durability can be categorized as follows:

Professional grade: These blades are designed for heavy-duty use in industries and construction sites. Examples in this segment include the '

DEWALT DW3128P5', which features a 10-inch blade with 60 teeth, carbide construction, and a specially formulated anti-stick coating for increased durability.DIY/Home use: These blades cater to occasional users or home projects. Notable examples are the 'Diablo D0724X' and the '

Bosch DCB1060'. The Diablo blade boasts a tough steel plate and carbide teeth, ensuring long blade life and precise cuts. The Bosch blade features ultra-sharp carbide teeth and it is designed for fast and smooth cuts in wood and composite materials. Both are excellent choices for those seeking durable blades for DIY tasks at home.

Blade Resharpening

Over time, saw blades can become dull and lose their cutting efficiency. Therefore, it is essential to select blades that can be easily and effectively resharpened.

One great option for blade resharpening is the FREUD D0770A Diablo 7-1/4-inch 70-Tooth. This blade features Freud's high-density carbide with titanium fused teeth, which allow for multiple resharpenings without compromising the blade's durability or cutting performance. It also has laser-cut stabilizer vents that reduce vibration and provide enhanced accuracy.

Another noteworthy choice is the `Freud LM72R010 10-Inch 24 Tooth FTG Thin Kerf

Blade Compatibility

Blade Compatibility

Choosing the right saw blade depends on its compatibility with your specific saw. Not all saw blades are compatible with every type of saw, so it’s important to consider the compatibility factor before making a purchase. For instance, if you own a circular saw, you will need to choose a saw blade specifically designed for circular saws, such as the Freud D0760A Diablo 7-1/4" x 60-Tooth Ultra Fine Finish Circular Saw Blade. This high-quality carbide blade features a thin kerf design for fast and smooth cuts and is specifically designed for use with circular saws, ensuring perfect compatibility. Another example is the DEWALT DW3106P5 60-Tooth Crosscutting and 32-Tooth General Purpose Saw Blade Combo Pack. This handy combo pack includes two high-quality blades that are compatible with miter saws and table saws, making it a versatile choice for different cutting applications. Keep in mind the saw blade’s compatibility with your specific saw to ensure optimal performance and safety.

Blade Noise Level

Noisy saw blades can be disruptive and tiring to work with, while quieter blades provide a more comfortable and enjoyable experience. Some blades are specifically designed to reduce noise levels during operation. For example, the Freud LU89R010 Thin Kerf Ultimate Plywood and Melamine Blade features an anti-vibration design and laser-cut stabilizer vents that significantly reduce noise and provide smoother cuts. Another option is the Diablo Steel Demon D1472CF Cermet II Carbide Metal Cutting Saw Blade, which incorporates noise-reducing laser-cut body slots along with a special blade geometry that minimizes noise and vibration.

In the market, saw blades can be categorized into various segments based on the noise level they produce. In the low noise category, we have blades like the Makita A-94839 80-Tooth Carbide Blade, renowned for its noise reduction design and ultra-quiet operation. There are also mid-range noise level blades, such as the Irwin Tools Marathon-Inch Miter Saw Blade, which offers balanced noise reduction without compromising performance. For those seeking very minimal noise levels, higher-end options like the Forrest WW05PC Woodworker II Blade are available, known for their virtually silent operation thanks to advanced design elements.

Blade Vibration

Blade vibration occurs when the blade moves excessively while cutting, resulting in less precise and smooth cuts. To minimize vibrations, look for saw blades with anti-vibration features. One example is the Freud D1284LF Diablo Laminate & Wood Flooring Blade. This blade incorporates a stabilizer control feature, which helps to reduce vibration and result in more accurate cuts. Another option is the Makita A-93681 10-Inch Miter Saw Blade. This blade is manufactured with carbide tips specifically designed to dampen vibrations, allowing for cleaner and smoother cuts. Both of these blades are examples of how anti-vibration features can enhance cutting performance.

Blade Heat Resistance

This refers to the blade's ability to withstand heat generated during the cutting process. Blades with high heat resistance are less prone to warping or dulling, ensuring a longer lifespan and efficient cutting performance. One example of a saw blade known for its impressive heat resistance is the 'Freud D1040X Diablo 10-Inch' Fine Finish Saw Blade. With its Perma-SHIELD coating and heat expansion slots, this blade dissipates heat effectively and provides clean, accurate cuts without overheating. Another option to consider is the 'IRWIN Tools Marathon 24-Tooth' Saw Blade. This blade features carbide teeth that resist heat buildup, making it ideal for cutting through a variety of materials with ease and durability. These two choices highlight the importance of Blade Heat Resistance in choosing the best saw blades for your needs.

Blade Anti-Kickback

This feature helps reduce the risk of sudden, powerful backward movements that can occur during cutting, preventing potential accidents and ensuring safety. Several top-rated saw blades on the market offer excellent anti-kickback capabilities. For example, the Diablo D1040X features a kickback-reducing design with a thin laser cut kerf that provides fast and clean cuts while minimizing the possibility of kickback. Another option is the Freud LU91R blade, which boasts a unique chip-clearance design that helps to prevent kickbacks and ensures smoother cuts. Both of these blades receive high ratings for their anti-kickback features, making them reliable choices for users who prioritize safety.

Blade Chip Limitation

The chip limitation refers to the ability of the blade to prevent wood chips from being extracted efficiently during cutting, which can result in poor cutting quality and potential damage to the blade. Different saw blades have varying chip limitations, and it is crucial to select one that meets your specific cutting needs.

One popular example of a saw blade with excellent chip limitation is the DEWALT DW3106P5 10" Saw Blade Combo Pack. This pack includes two blades, one with 60 teeth and another with 32 teeth, offering versatility for different cutting tasks. These blades feature an anti-stick rim that helps minimize gum-up and improve chip extraction, ensuring cleaner and smoother cuts. Another option worth considering is the Freud D1060X Diablo 10" Saw Blade, which boasts a laser-cut stabilizer that helps reduce vibration and provide precise, chip-free cuts. Its high-density carbide teeth provide long-lasting performance and excellent chip evacuation. Both of these saw blades are widely recognized for their exceptional chip limitation capabilities, making them reliable choices for various woodworking needs.

Blade Lubrication

Lubrication not only helps to reduce friction and heat during cutting but also prolongs the blade's lifespan and ensures smooth and precise cuts. There are several lubrication options available in the market, such as cutting oils, aerosol lubricants, and wax sticks, each offering distinct features and advantages for different applications.

Cutting oils are commonly used for metal cutting and provide excellent lubrication and cooling properties. Products like RIDGID - Pipe Threading Oil and Tap Magic - Cutting Fluid are highly recommended for use with metal cutting saw blades.

Aerosol lubricants, such as DriCote - Dry Lubricant and 3-IN-ONE - Professional Grade Dry Lube, are ideal for woodworking applications. These lubricants leave a thin film on the blade, reducing friction and preventing resin buildup during cutting.

Wax sticks, like Stick Wax - Premium Stick Lubricant and Bostik - GlideCote, are a convenient and hassle-free option for minimizing friction and improving the smoothness of cuts. These sticks can be directly applied onto the saw blade for quick and easy lubrication.

Considering the specific terms and data present within product specifications, users can explore different lubrication options based on their intended applications, such as metal cutting, woodworking, or general purpose. Each lubrication type has its benefits, and selecting the right lubrication method will ultimately enhance cutting performance and maximize the longevity of saw blades.

Blade Safety Features

A good saw blade should have features that minimize the risk of accidents and ensure a safe working environment. For instance, the Diablo D1084L is a great example of a saw blade that prioritizes safety. It is equipped with laser-cut stabilizer vents that reduce noise and vibration, offering a smooth and stable cutting experience. Additionally, it features an anti-kickback design, an essential safety feature that prevents the blade from getting jammed in the workpiece, reducing the chance of accidents.

Other saw blades with excellent safety features include the Freud LU86R and DEWALT DW7140PR which both have expansion slots that prevent warping during expansion and contraction in the blade. Another notable example is the Makita A-93681, which boasts a laser-cut blade body design for straighter cuts and reduces the chance of binding. These blades are all great options when safety is a top priority.

Manufacturer Reputation

Opting for a well-established and reliable brand ensures that you are investing in a product that is known for its quality and performance. Some reputable manufacturers in the saw blade industry include DEWALT, Freud, Bosch, and Diablo. For example, the DEWALT DW3106P5 is a set of premium circular saw blades that are intended for framing and crosscutting applications. It features ultra-sharp carbide teeth and anti-stick coating for smooth and accurate cuts. The Freud LU83R010 is another outstanding option for ripping and crosscutting, designed with anti-vibration technology and laser-cut, high-grade steel plates. Additionally, the Bosch DCB1072 Daredevil framing blade is known for its durability and long blade life due to its TiCo hi-density carbide teeth and hardened plates. Choosing saw blades from reputable manufacturers ensures you are getting a product that is backed by years of expertise and quality assurance.

Price

When it comes to price, it is crucial to find a saw blade that fits your budget while still delivering excellent performance. One option to consider is the 'DEWALT DW3106P5', a pack of two saw blades with a reasonable price point. These blades feature a 10-inch diameter, 60 teeth with a thin kerf design, which provides faster and more efficient cutting. Another cost-effective choice is the 'Freud D1050X' ultimate crosscutting saw blade. This blade has a 10-inch diameter, 50 teeth, and a non-stick coating that reduces friction and provides smoother cuts.

In the market, saw blades can be segmented based on their price range. For budget-friendly options, the 'Craftsman 9-37041' and 'Irwin Tools Marathon' series offer cost-effective solutions without compromising on quality. For those looking for a mid-range option, the 'Diablo D1050X' and 'Makita A-93681' saw blades provide professional-grade performance at a more affordable price point. And for customers who are willing to invest in premium quality blades, the higher priced but top-performing options include the 'Freud LU83R010' and 'Forrest WW10407125'. It's important to compare prices and features among different brands and models to find the best saw blade that suits both your needs and budget.

Variety of brands

Different brands of saw blades offer various pros and cons that cater to different user needs and preferences. Some popular brands include Freud, Dewalt, and Bosch, each with their own unique features.

For instance, Freud provides a wide range of saw blades that are designed for different applications. Their Diablo General Purpose Blades are known for their durability and versatility, making them suitable for various cutting tasks. On the other hand, Dewalt blades are best known for their precision cutting and long edge retention. For those who prioritize higher speed and efficiency, Bosch offers the Bosch Daredevil Blade, which boasts a specialized design for faster cutting.

It is essential to research and compare the pros and cons of different brands to find the right saw blade that suits your specific woodworking needs. Don't forget to consider factors such as blade material, tooth configuration, and the type of saw you are using, as these aspects can also significantly impact the performance of the blade.